Advanced Delivery Mechanism Demonstration Simulator

Product Details:

- Temperature Resistance Up to 80C

- Speed Range 0 100 rpm (adjustable)

- Power Supply AC Mains

- Features Replaceable modules, Transparent observation panels, Inbuilt safety features, Easy to assemble/disassemble

- Display Type Digital LED Display

- Accuracy 0.5%

- Glass Type Acrylic (Transparent)

- Click to View more

X

Advanced Delivery Mechanism Demonstration Simulator Price And Quantity

- 100 Box

Advanced Delivery Mechanism Demonstration Simulator Product Specifications

- Educational, Research, Laboratory Experiments on Delivery Mechanisms

- High-Grade Stainless Steel, Transparent Acrylic Panels

- Stainless Steel, Acrylic

- 0.5%

- Rectangular

- Acrylic (Transparent)

- Manual and Digital Control

- 220 V

- 600 mm x 400 mm x 400 mm

- AC Mains

- 0 100 rpm (adjustable)

- Up to 80C

- 220V, 50Hz, 100W

- Mechanical Demonstrator

- 10 Litres

- Replaceable modules, Transparent observation panels, Inbuilt safety features, Easy to assemble/disassemble

- Demonstration Simulator

- Digital LED Display

Advanced Delivery Mechanism Demonstration Simulator Trade Information

- 500 Box Per Day

- 1 Week

Product Description

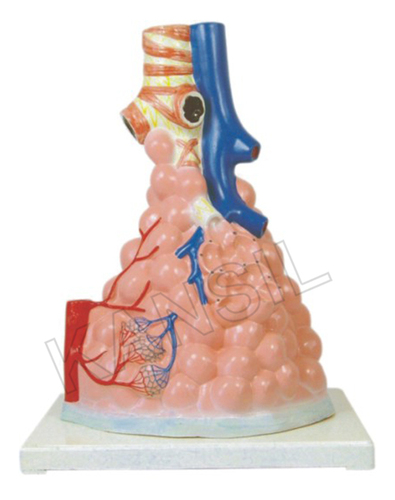

Advanced Delivery Mechanism Demonstration Simulator

- Demonstrate the whole process of delivery;

- Demonstrate the fetus, umbilical cord and placenta of vacuum-assisted delivery, flexible fetal joint and multiple normal and abnormal positions of fetal delivery can be showed;

- Can practice and master the comprehensive skills of normal labor, abnormal labor (dystocia), midwifery and perineum protection

- Available training of multiple pregnancy (twin pregnancy) Component: A (Matrix For Delivery Demonstration) + B (Fetus For Demonstration)

Intuitive Operation and Digital Display

The simulator features semi-automatic operation for precise fluid flow control. With its digital LED display, users receive real-time feedback and accurate measurements (0.5%), making demonstrations both engaging and reliable, while ensuring accessibility for both beginners and advanced users.

Versatile Visualization and Modular Design

Transparent acrylic panels allow clear observation of internal fluid dynamics. The system supports a range of educational and research activities, with replaceable modules and easy assembly or disassembly. This flexibility enables a diverse array of delivery mechanism experiments in a single compact unit.

Durability and Easy Maintenance

Manufactured from high-grade stainless steel and export-grade packaging, the simulator is built to last. The design ensures low maintenance needs and resistance to temperatures up to 80C. All fittings and accessories are included, facilitating effortless setup and operation in any laboratory setting.

FAQs of Advanced Delivery Mechanism Demonstration Simulator:

Q: How does the simulator demonstrate fluid flow delivery mechanisms?

A: The simulator uses transparent acrylic panels to allow clear visualization of fluid movement within its internal modules. By adjusting the flow parameters via digital or manual controls, users can observe various delivery mechanisms in action and analyze their characteristics in real time.Q: What types of educational and research applications is this equipment suitable for?

A: This apparatus is ideal for classroom demonstrations, laboratory experiments, and research investigations related to mechanical delivery systems, fluid dynamics, and engineering principles. Its versatility makes it suitable for use in schools, colleges, universities, and research institutions.Q: When should I use the manual versus the digital control mode?

A: Manual control is best used for hands-on learning experiences or when gradual, incremental adjustments are required. Digital control is ideal for precise tuning, reproducible results, and demonstrations where consistently accurate settings are necessary.Q: Where can the simulator be installed, and what are its space requirements?

A: Designed for tabletop use, the simulators compact dimensions (600 mm x 400 mm x 400 mm) make it suitable for most laboratory benches, demonstration rooms, and classroom environments. It requires only standard AC mains (220V) and minimal workspace for operation.Q: What is the process for setting up the simulator and starting a demonstration?

A: Setup involves connecting the standard pipe fittings, filling the 10-litre tank, attaching any required modules, and plugging in the power supply. After switching on the equipment, users can set their desired speed and control parameters, then observe and record the fluid flow behavior.Q: How does the modular design benefit users during laboratory experiments?

A: The modular components can be easily replaced or reconfigured, enabling the demonstration of various mechanisms and facilitating different experiment setups. This allows educators and researchers to tailor demonstrations to specific learning objectives or research questions without complex reassembly.Q: What maintenance is required to keep the simulator functioning optimally?

A: The simulator is designed to be low maintenance. Routine cleaning with mild solutions and checking for secure fittings are usually sufficient. Detailed instructions are provided in the included manual, ensuring minimal downtime and dependable operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Human Anatomical Models' category

|

N. C. KANSIL & SONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese